Facilities

| No. | Equipment | Name/Model | Description |

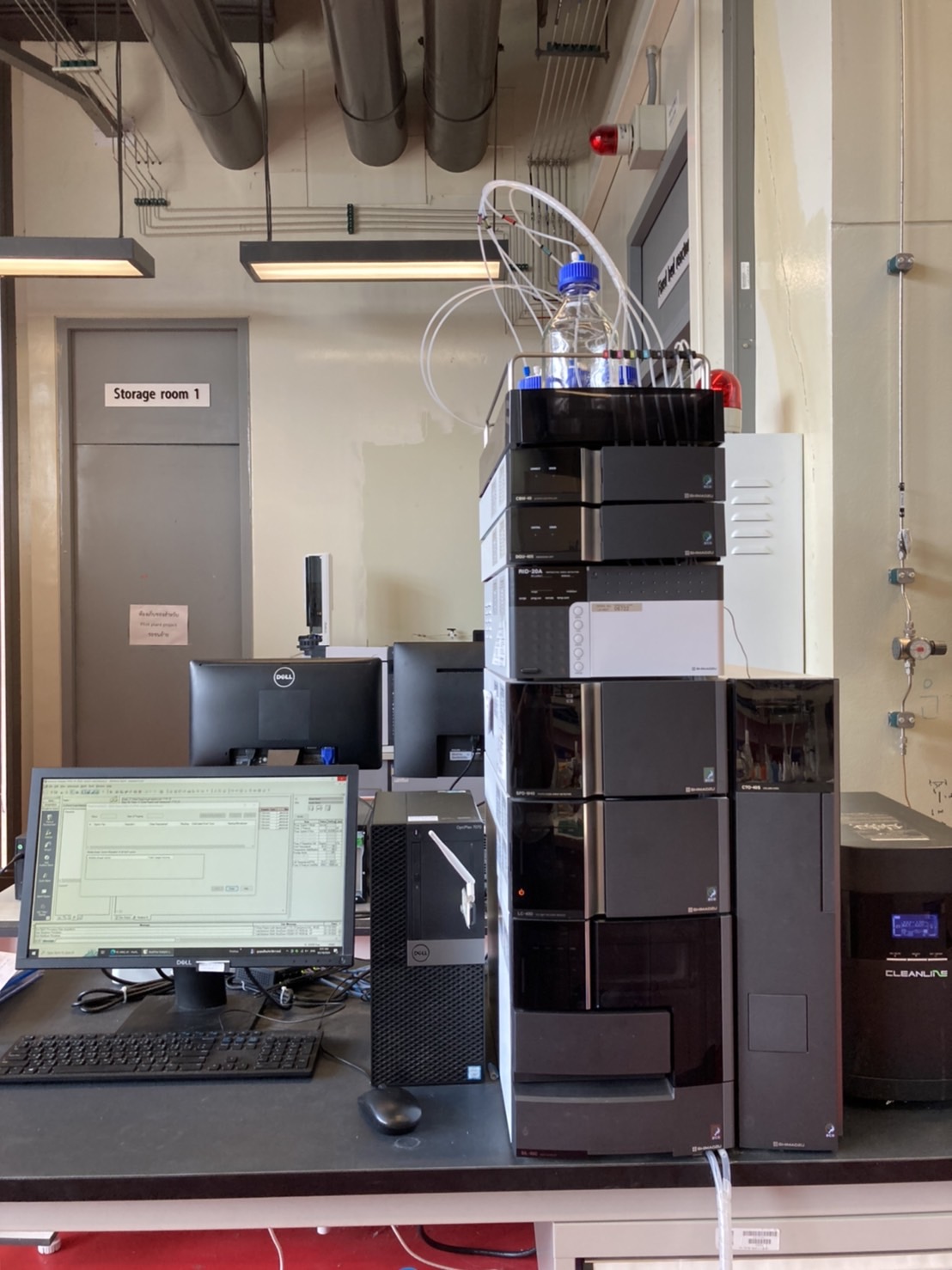

| 1 |  | High performance liquid chromatography (HPLC)

Model: Shimadzu | Analyzed product distribution in the liquid phase |

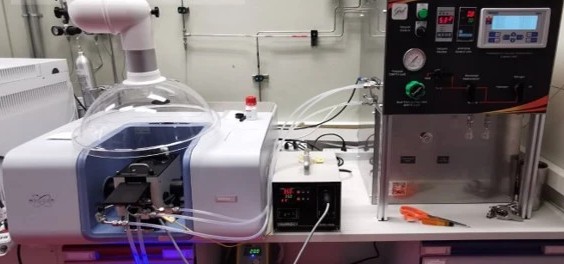

| 2 |  | Gas chromatography–mass spectrometry (GC-MS)

Model: Agilent | Analyzed unknown compounds |

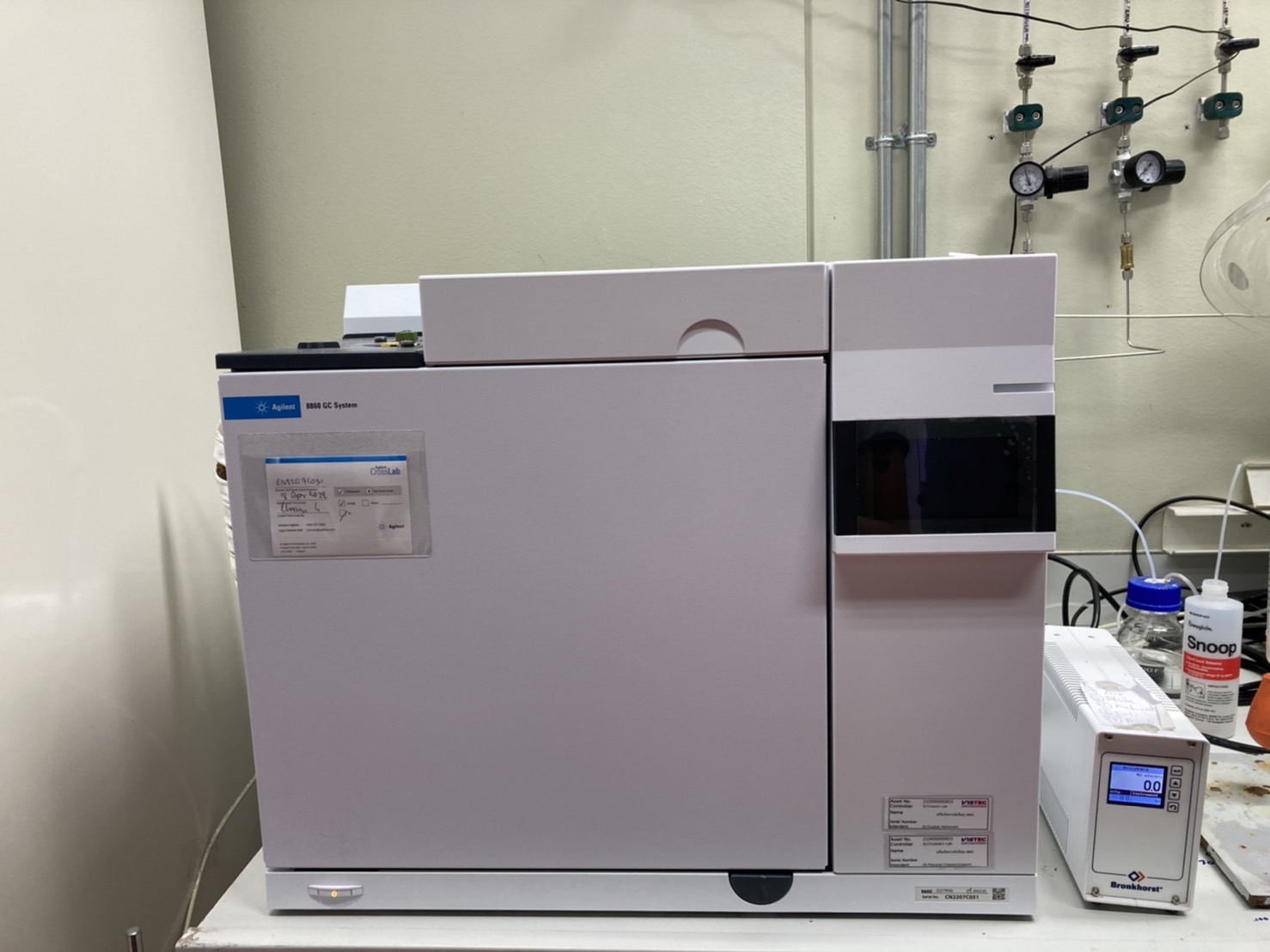

| 3 |  | Gas chromatography (GC) Model: Agilent | Analyzed product distribution in the gas phase |

| 4 |  | Physisorption analyzer Model: Micromeritics. ASAP 2000 | Surface area, pore volume analysis |

| 5 |  | In-situ Pyridine FT-IR Model: Bruker | Identify Bronsted acid site and Lewis acid site |

| 6 |  | Chemisorption analyzer Model: MicrotracBEL/BELCAT | H2-TPR, O2-TPO, NH3-TPD, CO2-TPD, metal dispersion, metal reduction temperature, Identify coke formation, Acid-base properties |

| 7 |  | Transmission Electron Microscope (TEM) and energy dispersive X-ray spectroscopy (EDS)

Model: JEOL/JEM-ARM200F | Morphology, crystal planes, particle size, and elemental analysis of material |

| 8 |  | Scanning Electron Microscope (SEM) and energy dispersive X-ray spectroscopy (EDS) Model: JEOL/ISM-7610F | Morphology, particle sizes, elemental analysis of material |

| 9 |  | X-ray Diffractometer (XRD) Model: BRUKER/NEW D8 ADVANCE | Crystallographic structure of material |

| 10 |  | Wavelength-Dispersive X-ray Fluorescence Spectrometer (WDXRF) Model: S8 Tiger / BRUKER | Elemental composition analysis |

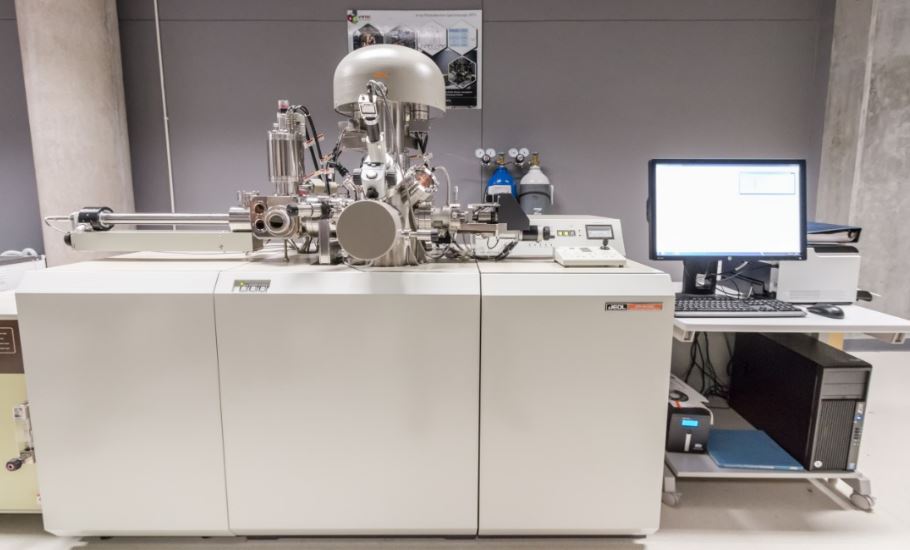

| 11 |  | X-ray Photoelectron Spectrometer (XPS) Model: JEOL/JPS-9010MC | Metal species |

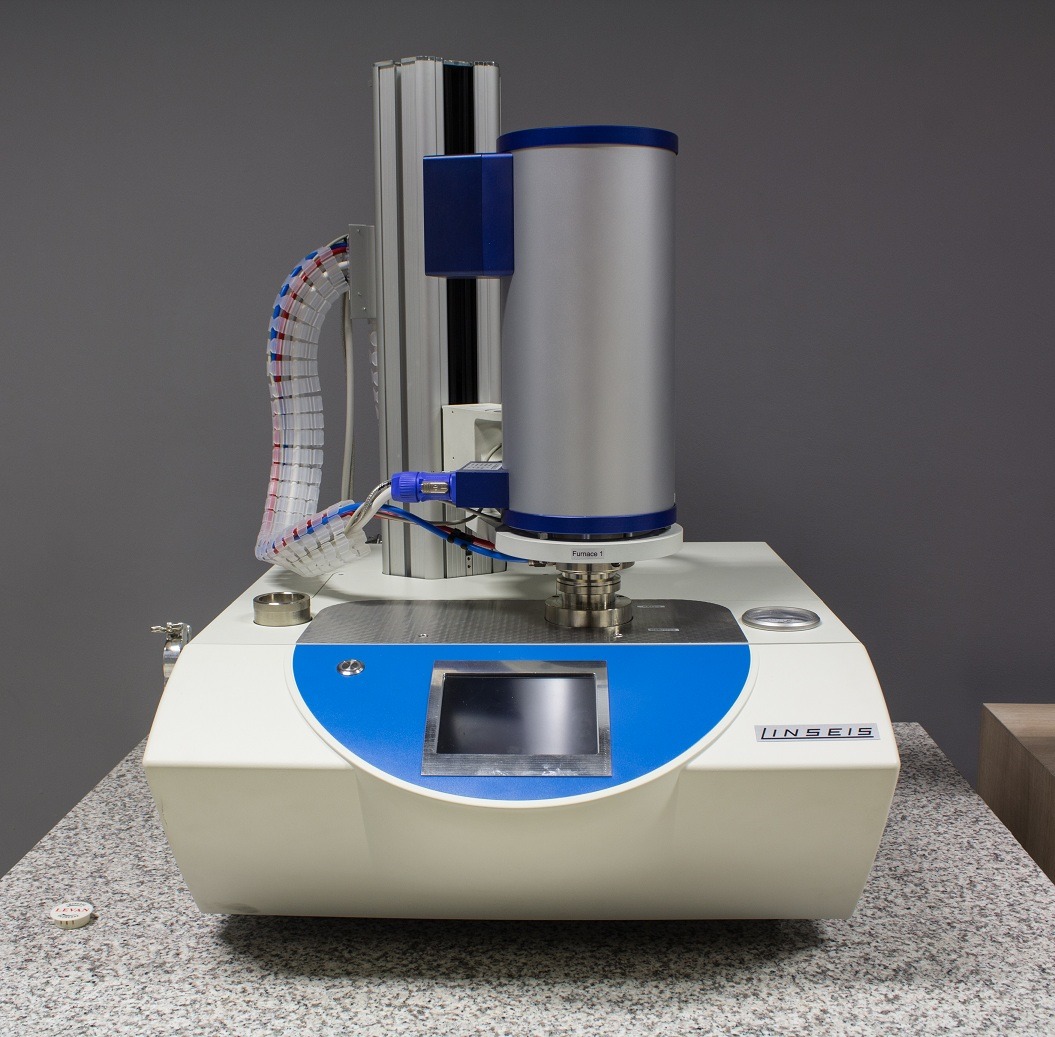

| 12 |  | Thermo-Gravimetric Analyzer and Differential Thermal Analyzer Model: Linseis/STA PT1600 | Measurement of thermal stability of materials |

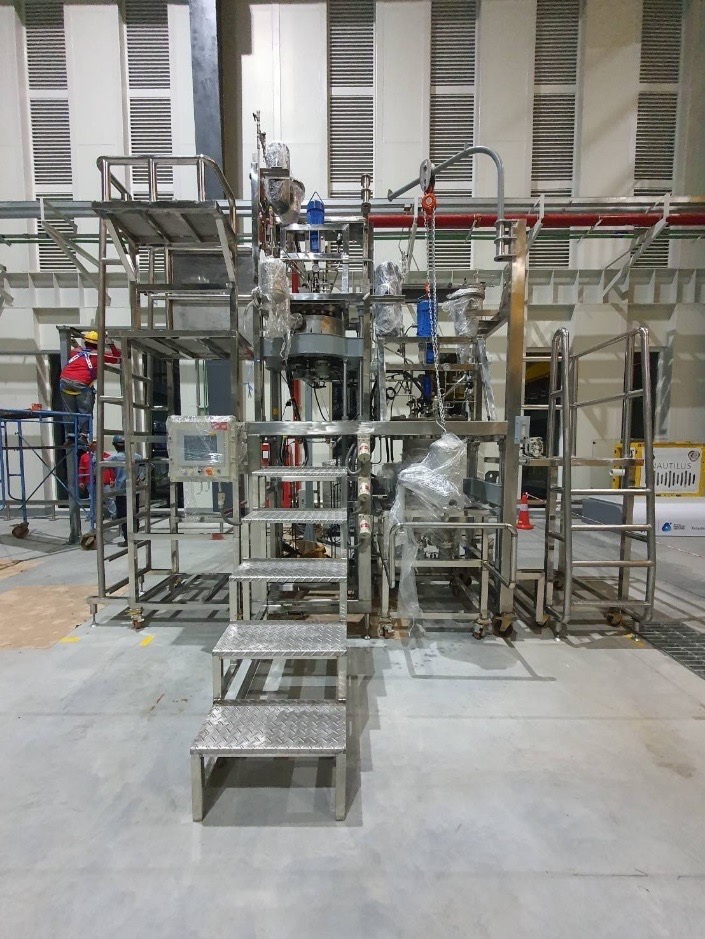

| 13 |

| Pilot plant -Fixed bed reactor -Batch reactor | -Fixed bed reactor for catalytic testing such as ethanol conversion -Batch reactor for zeolite synthesis |