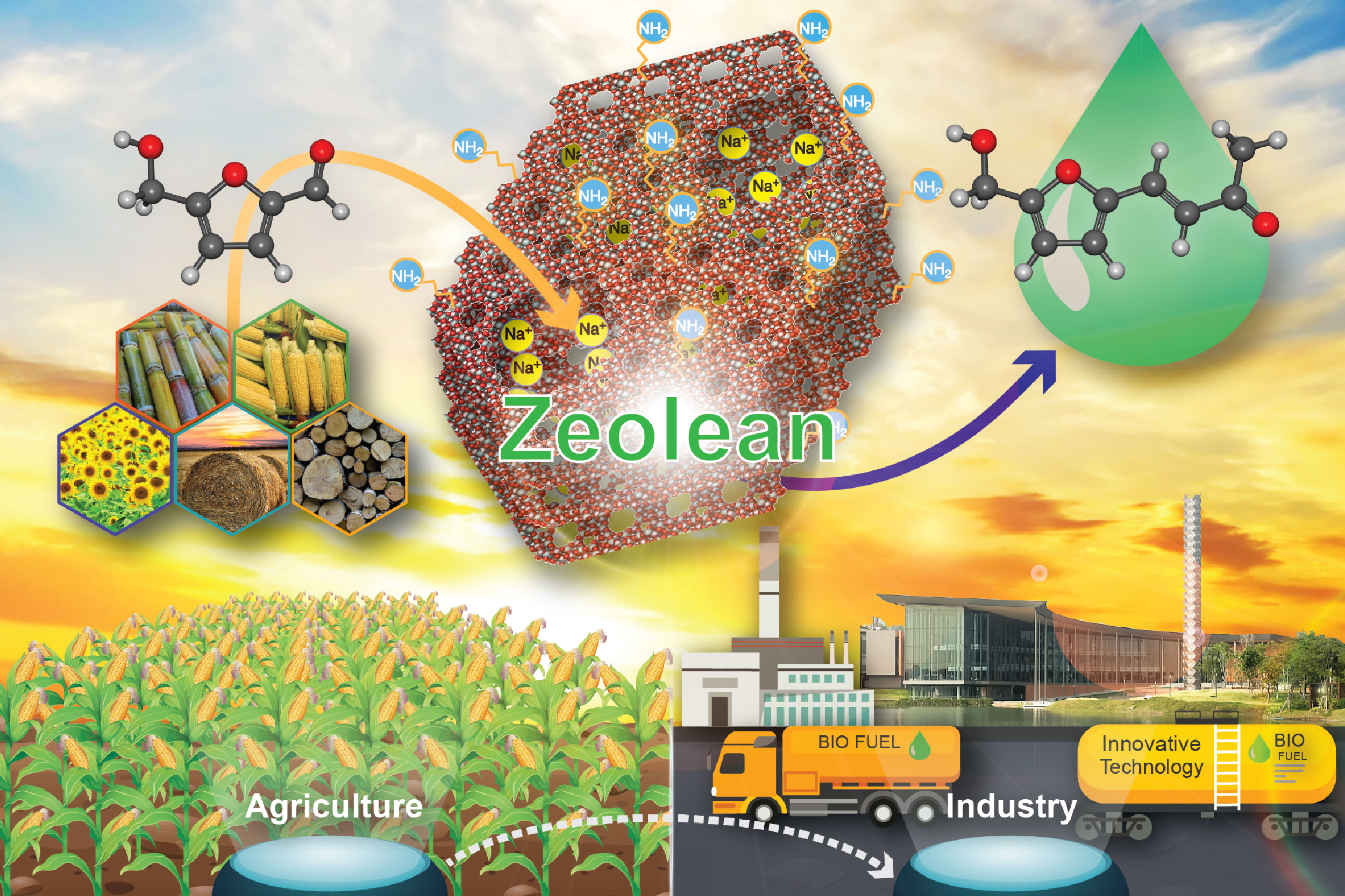

Bio-refinery is an emerging and transformative concept that mimics the functionality of petroleum refineries but relies on renewable biomass such as agricultural residues, lignocellulosic materials, and organic waste as feedstock. By integrating chemical, thermal, and electrochemical processes, bio-refineries aim to convert biomass into a broad spectrum of value-added products, including biofuels, platform chemicals, and biopolymers. This approach not only maximizes the utility of biomass resources but also supports a circular and low-carbon economy, positioning bio-refineries as a key pillar in sustainable chemical manufacturing and green energy development.

Moreover, our research focuses on the rational design of multifunctional catalysts and integrated reaction systems that can simultaneously valorize biomass-derived feedstocks and mitigate greenhouse gas emissions. This includes the co-electrolysis of HMF and CO₂, catalytic aromatization of bioethanol, and the utilization of waste-derived materials as sustainable catalyst supports all contributing to the realization of circular, energy-efficient, and decarbonized chemical processes. we have successfully demonstrated paired electrochemical systems that couple biomass oxidation at the anode with CO₂ reduction at the cathode, achieving excellent Faradaic efficiencies and minimizing energy input. We have also explored the conversion of bioethanol to aromatic hydrocarbons using zeolite-based catalysts, offering new possibilities for bio-aromatic production from renewable alcohols. At the same time, the incorporation of waste plastics and industrial by-products into catalyst design represents a unique avenue for converting multiple waste streams into high-performance materials.

By combining catalysis, electrochemistry, and materials science, our bio-refinery platform offers a scalable, modular, and sustainable solution for the next generation of green chemical production bridging the gap between fundamental research and real-world application.

Reference :

1. Bioethanol Upgrading to Renewable Monomers Using Hierarchical Zeolites: Catalyst Preparation, Characterization, and Catalytic Studies

Catalysts, 2021, 11(10), 1162.

2. Shetsiri, S.; Thivasasith, A.; Wannapakdee, W.; Saenluang, K.; Wetchasat, P.; Salakhum, S.; Nokbin, S.; Limtrakul, J.; Wattanakit, C.*

Sustainable production of ethylene from bioethanol over hierarchical ZSM-5 nanosheets.

Sustainable Energy & Fuels, 2019, 3, 115-126.

3. Pornsetmetakul, P.; Maineawklang, N.; Wattanakit, C.* Preparation of Metal-Supported Nanostructured Zeolite Catalysts and their Applications in the Upgrading of Biomass-Derived Furans: Advances and Prospects

ChemPlusChem. 2024 https://doi.org/10.1002/cplu.202400343

4. Nunthakitgoson, W.; Chaipornchalerm, P.; Sohail, A.; Thivasasith, A.; Wattanakit, C.* Ni-decorated carbon nanotubes (CNTs) derived from ethanol for electrooxidation of furan derivatives featuring H2 production

Chem comm. 2024 https://doi.org/10.1039/D4CC03356F

5. Chaipornchalerm, P.; Prasertsab, A.; Prasanseang, W.; Wattanakit, C.* Perspectives on Recent Advances in Hierarchical Zeolites for Bioethanol Conversion to Chemicals, Jet Fuels, and Carbon Nanotubes

EnergyFuels,2024 https://doi.org/10.1021/acs.energyfuels.4c02069

6. Prasertsab, A.; Leangsiri, W.; Salakhum, S.; Yomthong, K.; Ittisanronnachai,S.; Watcharasing, S.; Kiattikomol, P.; Wattanakit, C.* Transformation of Production Sand Waste to FAU and LTA Zeolites for Selective Moisture Adsorption and Ethanol Conversion

Topics in Catalysis (2023)

7. Rodaum, C.; Klinyod, S.; Nunthakitgoson, W.; Chaipornchalerm, P.; Liwathananukul, N.; Iarat, P.; Wattanakit, C.* Binder-free hierachical zeolite pellets and monoliths derived from ZSM-5@LDH composites for bioethanol dehydration to ethylene

ChemComm., 2022, https://doi.org/10.1039/D2CC02200A

8. Salakhum, S.; Prasertsab, A.; Klinyod, S.; Saenlung, K.; Witoon, T.; Wattanakit, C.* Sustainable transformation of natural silica-rich solid and waste to hierarchical zeolites for sugar conversion to hydroxymethylfurfural (HMF)

Microporous and Mesoporous Mater., 2021, 111252.

9. Shetsiri, S.; Thivasasith, A.; Wannapakdee, W.; Saenluang, K.; Wetchasat, P.; Salakhum, S.; Nokbin, S.; Limtrakul, J.; Wattanakit, C.* Sustainable production of ethylene from bioethanol over hierarchical ZSM-5 nanosheets.

Sustainable Energy & Fuels, 2019, 3, 115-126.

10. Suttipat, D.; Wannapakdee, W.; Yutthalekha, T.; Ittisanronnachai, S.; Ungpittagul, T.; Phomphrai, K.; Bureekaew, S.; Wattanakit, C.*

Hierarchical FAU/ZIF‑8 hybrid materials as highly efficient acid-base catalysts for aldol condensation.

ACS Applied Materials & Interfaces, 2018, 10, 16358-16366.

11. Salakhum, S.; Yutthalekha, T.; Chareonpanich, M.; Limtrakul J.; Wattanakit, C.* Synthesis of hierarchical faujasite nanosheets from corn cob ash-derived nanosilica as efficient catalysts for hydrogenation of lignin-derived alkylphenols.

Microporous and Mesoporous Materials, 2018, 258, 141-150.

12. Yutthalekha, T.; Suttipat, D.; Salakhum, S.; Thivasasith, A.; Nokbin, S.; Limtrakul J.; Wattanakit, C.*

Aldol condensation of biomass-derived platform molecules over amine-grafted hierarchical FAU-type zeolite nanosheets featuring basic sites.

Chemical Communications, 2017, 53, 12185—12188 (Back cover page).

13. Rodponthukwaji, K.; Wattanakit, C.*; Yutthalekha, T.; Assavapanumat, S.; Warakulwit, C.; Wannapakdee, W.; Limtrakul, J.

Catalytic upgrading of carboxylic acids as bio-oil models over hierarchical ZSM-5 obtained via an organosilane approach.

RSC Advances, 2017, 7, 35581-35589.