BIOE2C Project - First pilot plant for green carbon nanotube production in Thailand

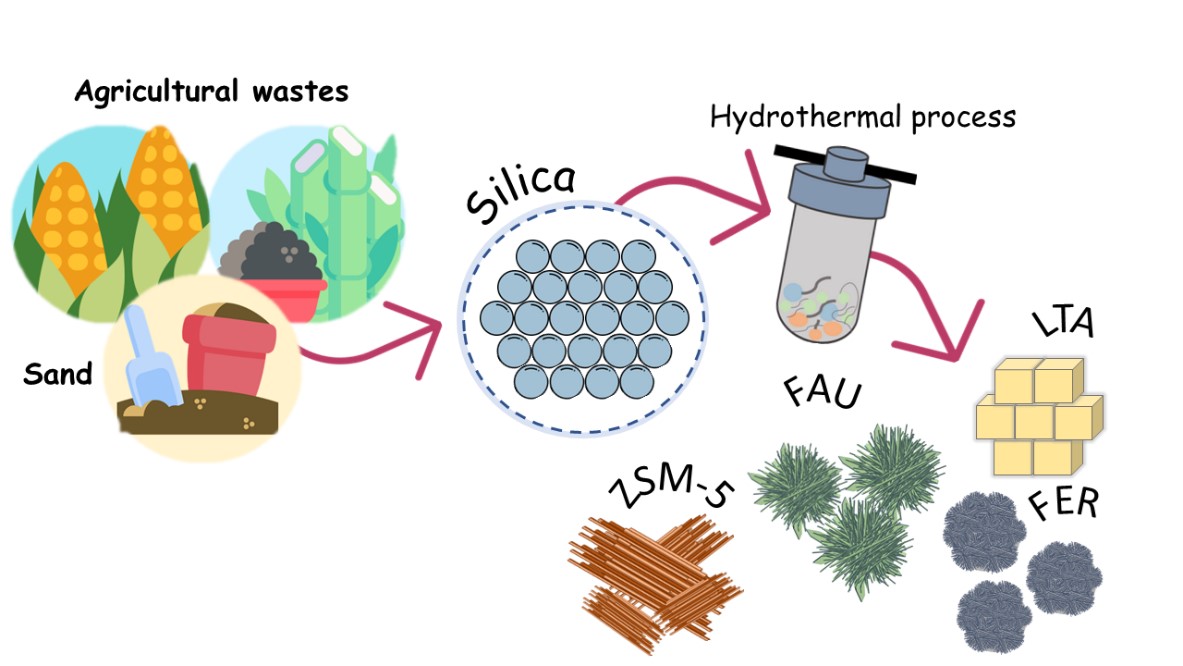

In this contribution, we explore a new concept to transform wastes such as agricultural wastes and silica/alumina wastes into industrial catalysts. In this case, various hierarchical zeolite frameworks have been synthesized by a simple hydrothermal process, such as LTA, FAU, ZSM-5, MOR, and FER as shown in Figure 1.

Figure 1. Illustration of the concept to transform agricultural wastes and sand into various types of zeolites.

To develop industrial catalysts, the rational design of binder-free hierarchical ZSM-5 monolith derived from zeolite@layered double hydroxides (LDH) composites via extrusion and 3D printing technologies has been demonstrated (Figure 2). For example, the designer catalyst applied in bioethanol dehydration boosts ethylene yield to over 96% due to the synergistic effect of zeolites and LDHs. This is the first example illustrating the design of highly efficient catalysts, which can be applied directly in industrial applications. Last but not least, we also illustrated the application of the designer catalysts for bioethanol dehydration to ethylene at a pilot-plant scale. This example opens up new perspectives for industrial catalyst design for bioethanol upgrading.

Figure 2. Illustration of the elaboration of binder-free hierarchical zeolite pellets or monoliths (Chem. Commun., 2022,58, 9618-962).