Service

1. Catalyst invention and customization

We are not only the supplier but also the research partner assisting our collaborators to develop new types of catalysts for a particular application. We ensure that from our strong research expertise regarding catalysis, our services can deliver the best solutions to customers. Here is an example:

- Catalyst for ethanol dehydration

- Catalyst for ethanol to acetaldehyde

- Catalyst for sugar conversion to HMF

- Catalyst for dehydrogenation of alkanes

2. Catalyst characterization

We also provide comprehensive catalyst characterization services, such as surface area analysis, porosity analysis, acidity, metal particle size, and metal dispersion. Moreover, we can help our clients to optimize their processes and improve their overall efficiency. Whether you are looking to develop new catalysts or improve the performance of existing ones, our catalyst characterization services can provide valuable information. Here is the lists of characterization techniques:

- X-Ray Fluorescence technology (XRF)

- Inductively Coupled Plasma Spectroscopy (ICP)

- Transmission Electron Microscopy (TEM)

- Scanning Electron Microscopy (SEM)

- Energy Dispersive X-Ray Spectroscopy (EDS)

- X-Ray Diffraction (XRD)

- H2-temperature programmed reduction (H2-TPR)

- Temperature-programmed oxidation (TPO)

- Temperature-programmed desorption of ammonia (NH3-TPD)

- Temperature-programmed desorption of carbon monoxide (CO-TPD)

- N2 adsorption-desorption isotherm and BET analysis

- Thermogravimetric analysis (TGA)

- Raman spectroscopy

- UV-Vis spectroscopy

- Fourier Transform Infrared (FTIR) Spectroscopy

- In-Situ Fourier Transform Infrared Spectroscopy

- Details

- Category: Products

About "V-CAT"

V-CAT is the part of the Porous Heterogeneous Catalysis Center (PHCC), School of Energy Science and Engineering, Vidyasirimedhi Institute of Science and Technology (VISTEC). Our passion is to transfer the scientific knowledge regarding the catalyst design to the potential applications including biomass conversion to produce fine chemicals and materials, petrochemical and refining, waste, and CO2 utilization.

We transferred the innovation from laboratory to pilot plant scale. The main focus of our new catalysts is based on the synthesis of hierarchical zeolites with various functionalities. For example, we have successfully developed several hierarchical zeolite frameworks with different Si/Al ratios. In addition, we can also modify our catalysts with the wide range of catalytic properties, for example, acid-base, and redox properties. Furthermore, to meet the sustainable development, we have developed our catalysts derived from both industrial and agricultural wastes, and it therefore can make the benefits to the environment.

Apart from the design of various hierarchical zeolites, we have also applied our catalysts in the wide range of catalytic processes including bioethanol to ethylene and carbon nanotubes, catalytic cracking of hydrocarbons to light olefins, hydrogenation of unsaturated hydrocarbons, propane dehydrogenation, glucose conversion to hydroxymethylfurfural (HMF) and 2,5-furandicarboxylic acid (FDCA).

Our commitment to quality extends to the people who are interested in an innovation of catalyst development for the novel applications in particular biorefinery. We offer high qualified catalysts (various forms of hierarchical zeolites) in several ways, for example, ion-exchanged hierarchical zeolites, redox-hierarchical zeolites, metal supported hierarchical zeolites for both powder and extruded forms. All of our catalysts have been produced in the high standard laboratory/pilot plant and are available in gram to kg scale with the qualified physical and chemical properties. The characteristics of our catalysts have been verified by means of high standard characterization techniques including X-ray diffraction, scanning electron microscopy (SEM), transmission electron microscopy (TEM), surface area analysis, chemisorption technique, and elemental analysis to ensure you that our catalysts meet with the maximum quality.

V-CAT is not only the supplier but also the research partner assisting our collaborators to develop new types of catalysts for a particular application. We ensure that from our strong research expertise regarding catalysis, our services can deliver the best solutions to customers.

- Details

- Category: Products

Contact us

E-mail : This email address is being protected from spambots. You need JavaScript enabled to view it.

Contact us : https://forms.gle/1KB97B4T1zozn3ky7

- Details

- Category: Products

Our Products

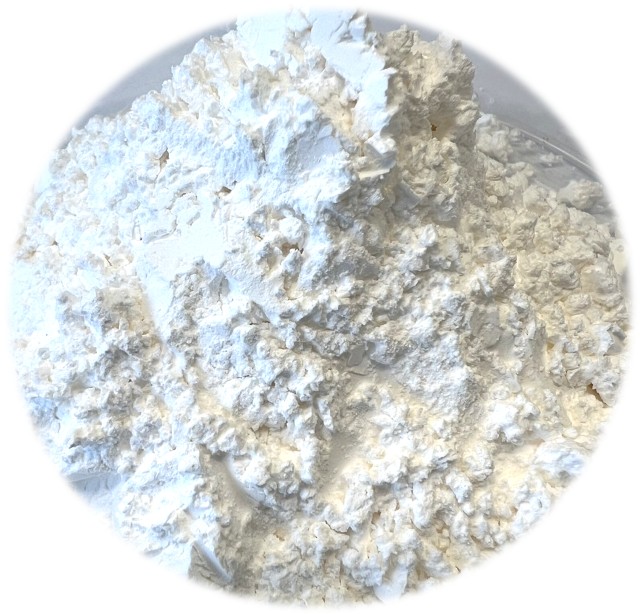

1. Zeolite powders

Hierarchical MFI nanosheets

| Zeolite code product | SiO2 | Norminal form | Surface area (m2/g) | Acidity (mmol/g) | Globular average particle size (nm) |

| VCAT 101 | 98 | Sodium | 434 | - | 180 |

Hierarchical MFI nanosheets play essential roles in various applications. For example, they can be applied in petroleum refining, coal conversion, aromatization, dehydrogenation, hydration, and biomass conversion.

Hierarchical ZSM-5 nanosheets

| Zeolite code product | SiO2/Al2O3 | Norminal form | Surface area (m2/g) | Acidity (mmol/g) | Globular average particle size (nm) |

| VCAT 102 | 20 | Sodium | 432 | - | 140 |

| VCAT 103 | 20 | Hydrogen | 561 | 0.30 | 140 |

| VCAT 104 | 40 | Sodium | 434 | - | 194 |

| VCAT 105 | 40 | Hydrogen | 568 | 0.22 | 167 |

| VCAT 106 | 70 | Sodium | 437 | - | 180 |

| VCAT 107 | 70 | Hydrogen | 562 | 0.17 | 185 |

| VCAT 108 | 100 | Hydrogen | 505 | 0.09 | 252 |

| VCAT 109 | 170 | Hydrogen | 589 | 0.08 | 255 |

Hierarchical ZSM-5 nanosheets play essential roles in various applications. For example, they can be applied in petroleum refining, coal conversion, aromatization, dehydrogenation, hydration, and biomass conversion.

Linde Type A

| Zeolite code product | SiO2/Al2O3 | Norminal form | Surface area (m2/g) | Acidity (mmol/g) | Globular average particle size (µm) |

| VCAT 201 | 1.2 | Sodium | 46 | - | 1.0 |

Linde Type A is used as an adsorbent, membrane, ion-exchange material, and molecular sieve, including as a catalyst for hydrocarbon conversion processes.

Nanosized Beta

| Zeolite code product | SiO2/Al2O3 | Norminal form | Surface area (m2/g) | Globular average particle size (nm) |

| VCAT 301 | 100 | Sodium | 466 | 200-300 |

Beta zeolite is normally applied as an active catalyst for reduction, alkylation, biomass conversion, hydrocracking, molecular sieve, adsorbent, and filtration.

Hierarchical Mordernite

| Zeolite code product | SiO2/Al2O3 | Norminal form | Surface area (m2/g) | Acidity (mmol/g) | Globular average particle size (µm) |

| VCAT 401 | 5.0 | Sodium | 536 | - | 1.5 |

| VCAT 402 | 5.0 | Hydrogen | 570 | 2.24 | 1.3 |

Moredenite zeolite is typically used in chemical conversion processes such as biomass conversion, reduction, isomerization, cracking, alkylation, and reforming.

2. Specialized catalysts

zeolite/layered double hydroxide composites

| Zeolite code product | MgO/Al2O3 | Surface area (m2/g) | Globular average particle size (nm) |

| VCAT 501 | 1.2 | 123 | 93 |

Zeolite/Layered double hydroxides (LDHs) composite are a class of solid materials that are typically used for catalysis, energy conversion, and polymer applications.

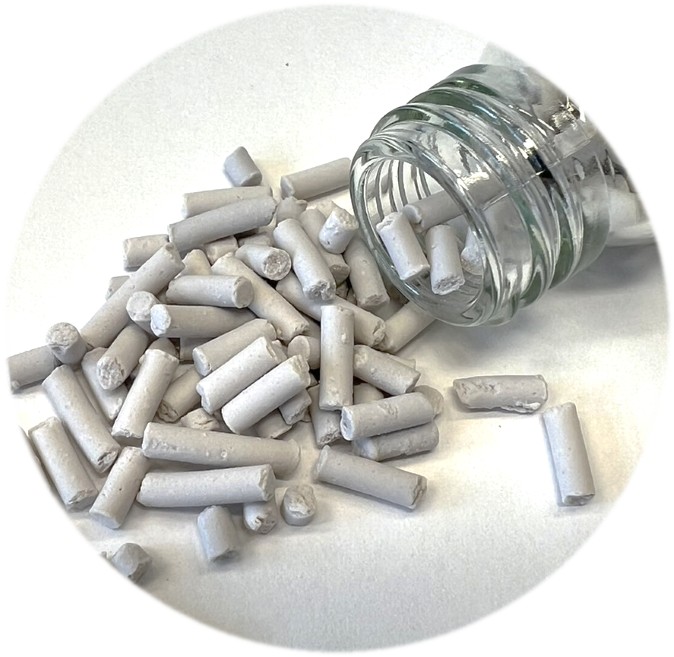

Extruded catalyst

| Zeolite code product | SiO2/Al2O3 | Norminal form | Catalyst diameter (mm) |

| VCAT 601 | 24-35 | Hydrogen | 3 |

| VCAT 602 | 24-35 | Hydrogen | 5 |

In addition, zeolite can combine with a binder to produce extruded catalysts with cylindrical geometry (pellets) that are ready to use for various catalytic processes. The beneficial aspect of the extruded catalyst is not only to prevent pressure drops in the system but also to inhibit the formation of aggregates. Specifically, customers can request the production of extruded catalysts related to the available powder of our products.

3. Customized catalyst

- Catalyst for ethanol dehydration

- Catalyst for ethanol to acetaldehyde

- Catalyst for sugar conversion to HMF

- Catalyst for dehydrogenation/dehydroisomerization of alkanes

- etc.,

We are a rapidly growing company with years of experience in critically producing zeolite at lab scale taking it further to upscale. Our focus extends to bulk production of various zeolites, zeolite/LDH composites, and extruded catalysts, specializing in customization for specific customer needs and applications. Our catalysts are finely tuned for maximum efficiency in diverse applications.

Our ultimate aim is to establish ourselves as a reliable manufacturer and supplier of zeolite-based products that adhere to high international standards. We consistently endeavor to excel beyond industry peers by consistently optimizing technology and perpetually innovating our product offerings. This aims to ensure enduring sustainability while adeptly catering to the ever-evolving needs of our esteemed customers.

- Details

- Category: Products

Facilities

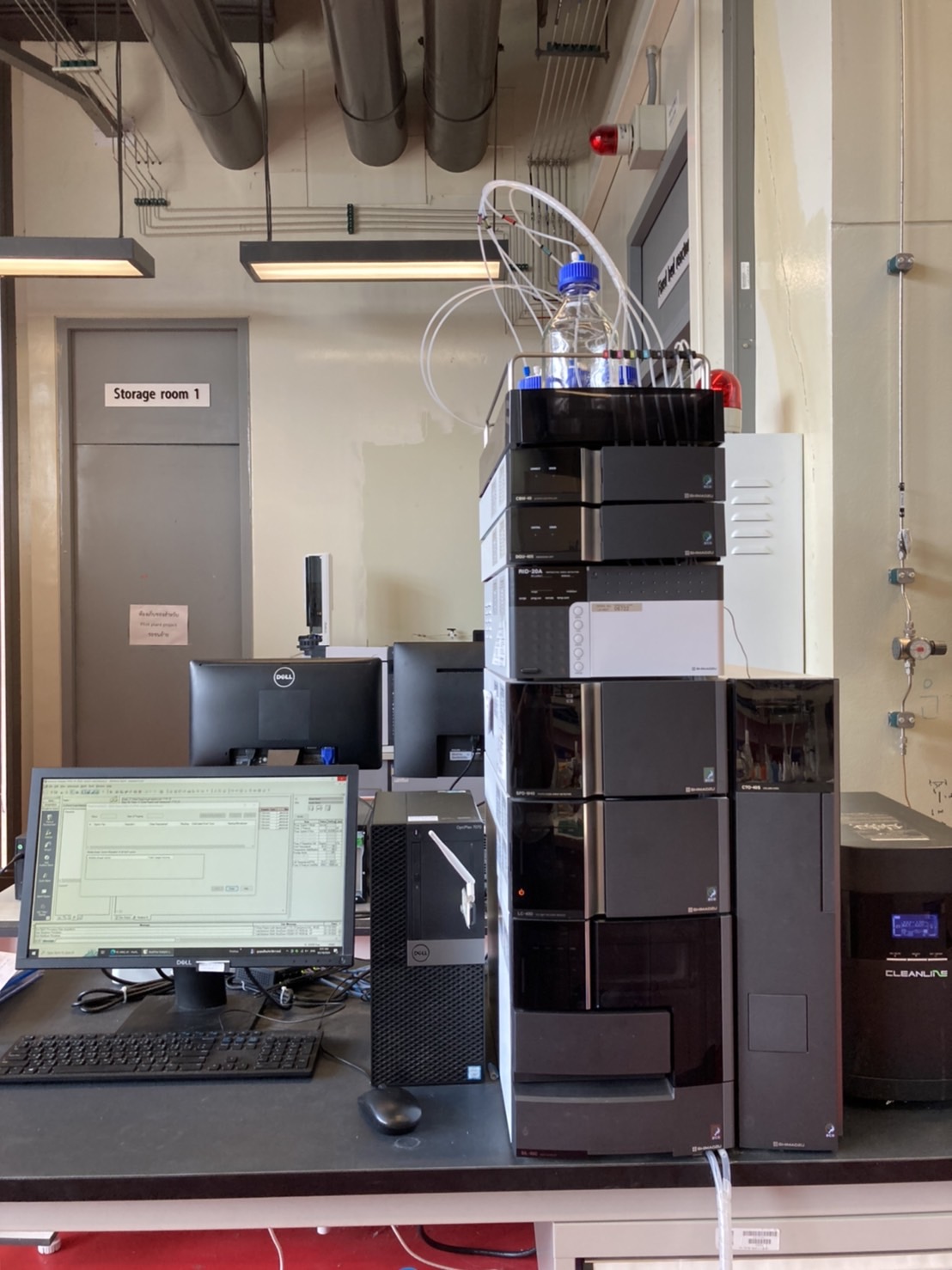

| No. | Equipment | Name/Model | Description |

| 1 |  | High performance liquid chromatography (HPLC)

Model: Shimadzu | Analyzed product distribution in the liquid phase |

| 2 |  | Gas chromatography–mass spectrometry (GC-MS)

Model: Agilent | Analyzed unknown compounds |

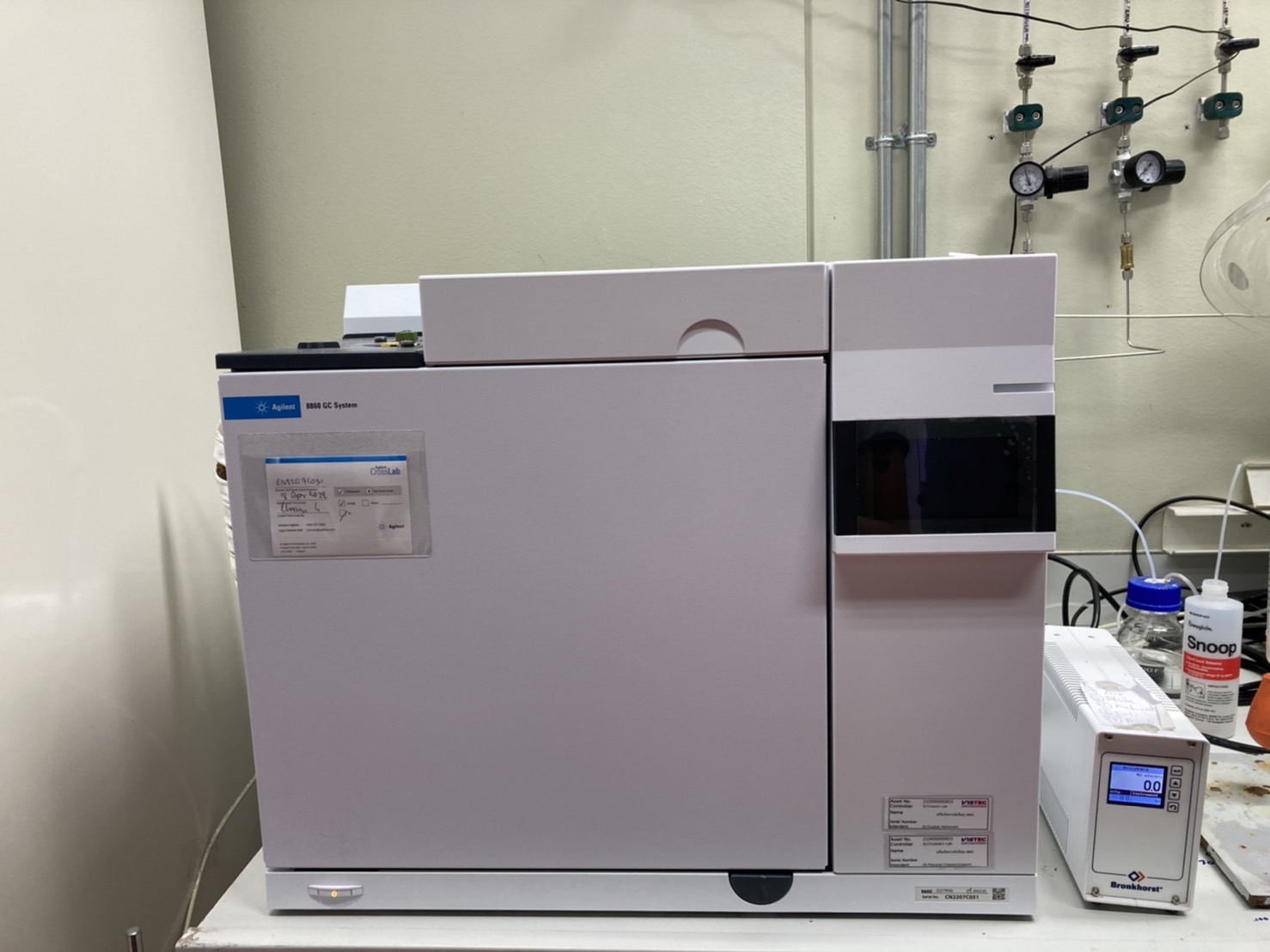

| 3 |  | Gas chromatography (GC) Model: Agilent | Analyzed product distribution in the gas phase |

| 4 |  | Physisorption analyzer Model: Micromeritics. ASAP 2000 | Surface area, pore volume analysis |

| 5 |  | In-situ Pyridine FT-IR Model: Bruker | Identify Bronsted acid site and Lewis acid site |

| 6 |  | Chemisorption analyzer Model: MicrotracBEL/BELCAT | H2-TPR, O2-TPO, NH3-TPD, CO2-TPD, metal dispersion, metal reduction temperature, Identify coke formation, Acid-base properties |

| 7 |  | Transmission Electron Microscope (TEM) and energy dispersive X-ray spectroscopy (EDS)

Model: JEOL/JEM-ARM200F | Morphology, crystal planes, particle size, and elemental analysis of material |

| 8 |  | Scanning Electron Microscope (SEM) and energy dispersive X-ray spectroscopy (EDS) Model: JEOL/ISM-7610F | Morphology, particle sizes, elemental analysis of material |

| 9 |  | X-ray Diffractometer (XRD) Model: BRUKER/NEW D8 ADVANCE | Crystallographic structure of material |

| 10 |  | Wavelength-Dispersive X-ray Fluorescence Spectrometer (WDXRF) Model: S8 Tiger / BRUKER | Elemental composition analysis |

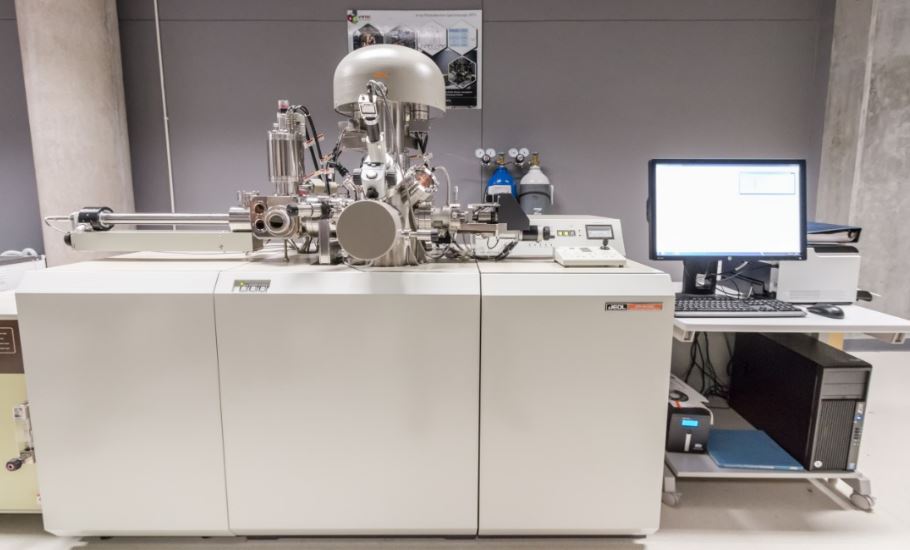

| 11 |  | X-ray Photoelectron Spectrometer (XPS) Model: JEOL/JPS-9010MC | Metal species |

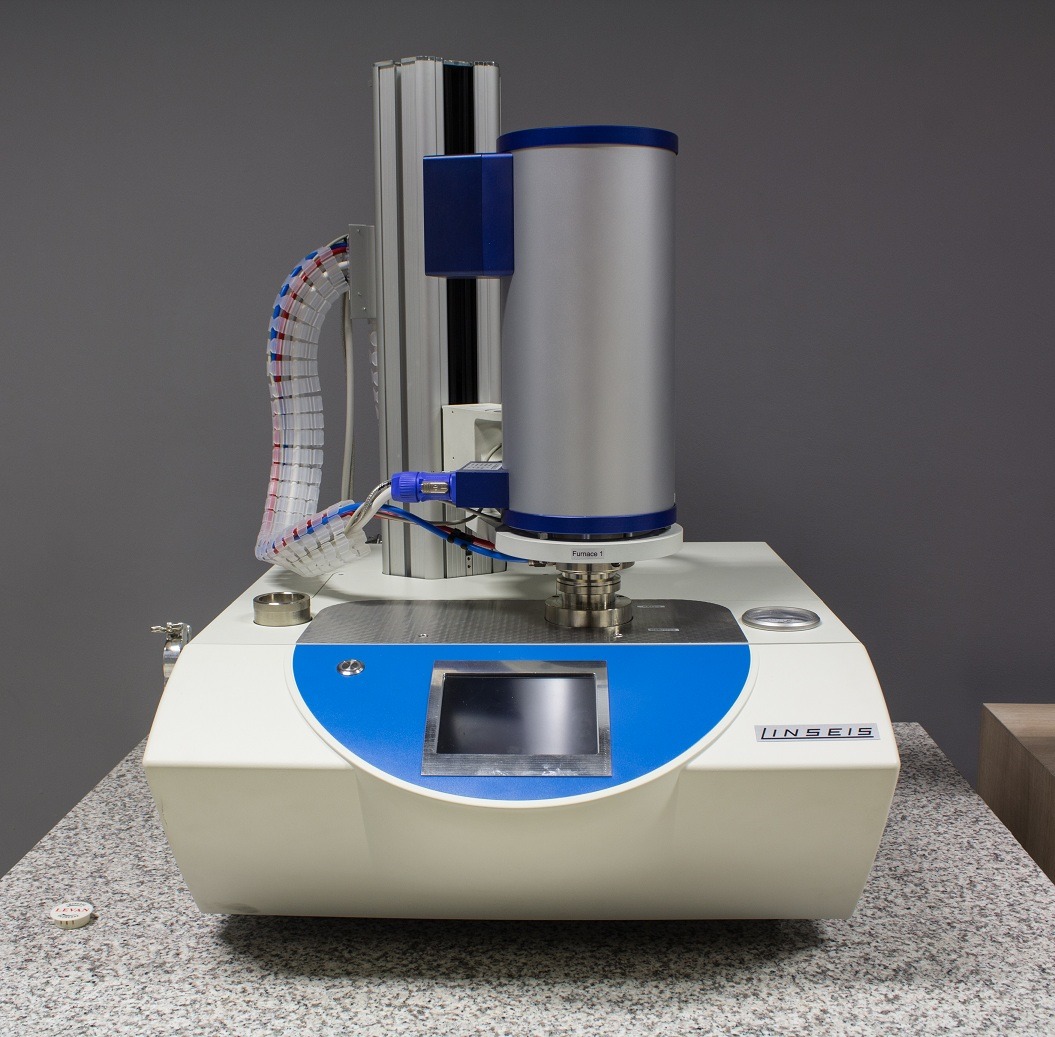

| 12 |  | Thermo-Gravimetric Analyzer and Differential Thermal Analyzer Model: Linseis/STA PT1600 | Measurement of thermal stability of materials |

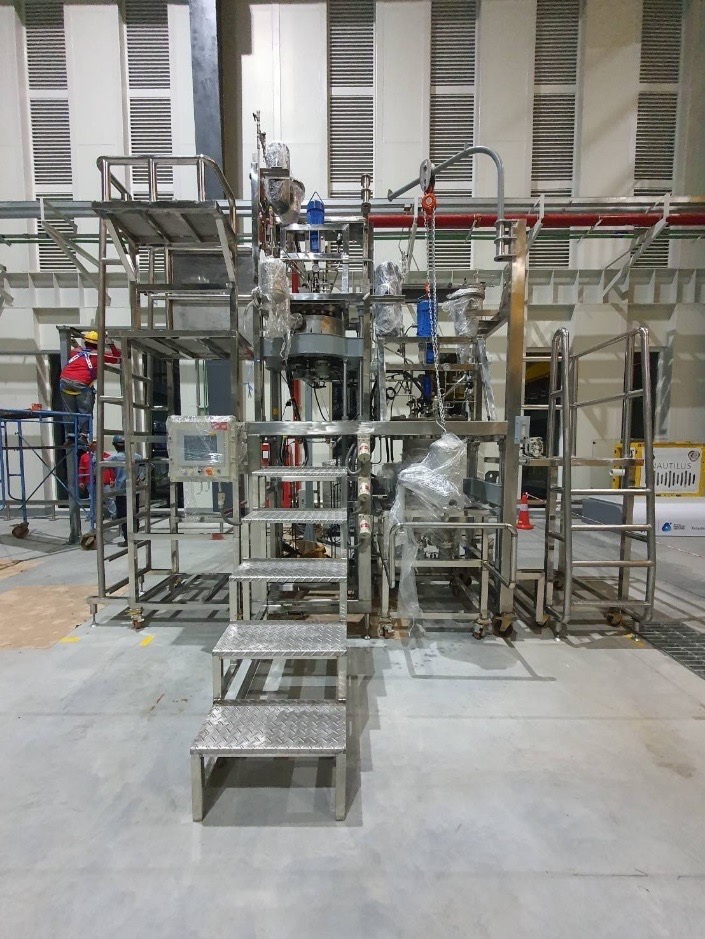

| 13 |

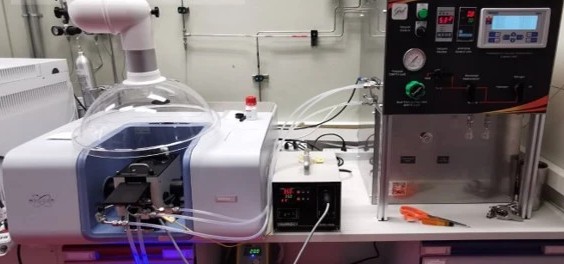

| Pilot plant -Fixed bed reactor -Batch reactor | -Fixed bed reactor for catalytic testing such as ethanol conversion -Batch reactor for zeolite synthesis |

- Details

- Category: Products

© 2024 phcc.vistec.ac.th